Tea Production

After picking, tea leaves will soon begin to wilt and oxidize if not dried quickly. Tea leaves turn progressively darker as a result of the breaking down of chlorophylland releasing of tannins . This enzymatic oxidation is called fermentation in the tea industry although there is no true fermentation.

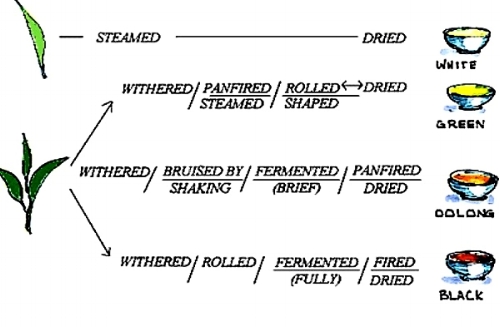

Oxidation is the key in tea making. Because the basic difference between 4 main types of tea is the degree of oxidation.

Below are some basic steps in tea making. The 4 main types of tea share very similar procedures but with variations in timing and in adding or eliminating some of the steps.

Photo created by Sjschen (source: wikipedia)

Picking/Plucking: Picking is done either by hand or machine. Hand picking is done when a high quality tea is being produced. It is done by pulling the leaves or flush (terminal bud and two young leaves) with a snap of the wrist that does not involve twisting, pinching or any kind of damage to the flush. When tea flushes are picked by machine there will be more broken leaves and partial flushes, which will result in a lower grade leaf style. Hand picking is more common where tea is grown on mountain slopes.

Wilting/Withering: The process of wilting or withering is done to remove excess water from the leaves and induce a very light oxidation (less than 5%). The leaves can be either put under the sun or left in a cool breezy room to pull moisture out from the leaves.

Bruising: In order to promote and quicken oxidation, the leaves may be bruised by tumbling in baskets or by being kneaded or rolled-over by heavy wheels. This also releases some of the leaf juices, which may aid in oxidation and change the taste profile of the tea.

Oxidation: For teas that require oxidation, the leaves are left on their own in a closed room where they turn progressively darker. In this process the chlorophyll in the leaves is enzymatically broken down, and its tannins are released or transformed. This process is referred to as fermentation in the tea industry, although no true fermentation happens since the process is not driven by microorganisms. The tea producer may choose when the oxidation should be stopped. For light oolong teas this may be anywhere from 5-40% oxidation, in darker oolong teas 60-70%, and in black teas 100% oxidation.

Kill-green: Kill-greenis done in order to stop the oxidation at a desired level. This process is accomplished by moderately heating tea leaves. Traditionally, the tea leaves are panned in a wok or steamed. Nowadays, inmass production, kill-green is done by baking or "panning" in a rolling drum.

Shaping: The damp tea leaves are then rolled to be formed into wrinkle strips. This is typically done by placing the damp leaves in large cloth bags, which are then kneaded by hand or machine to form the strips. This rolling action also causes some of the sap and juices inside the leaves to ooze out, which further enhances the taste of the tea. The strips of tea can then be formed into other shapes, such as being rolled into spirals, kneaded and rolled into pellets, or tied into balls and other elaborate shapes.

Drying: This is usually the last step in tea processing (some tea may require aging, curing (flavoring in addition to drying). Drying can be done by panning, sunning, air drying, or baking.